معلومات عنا

حقوق الطبع والنشر © 2024 Desertcart Holdings Limited

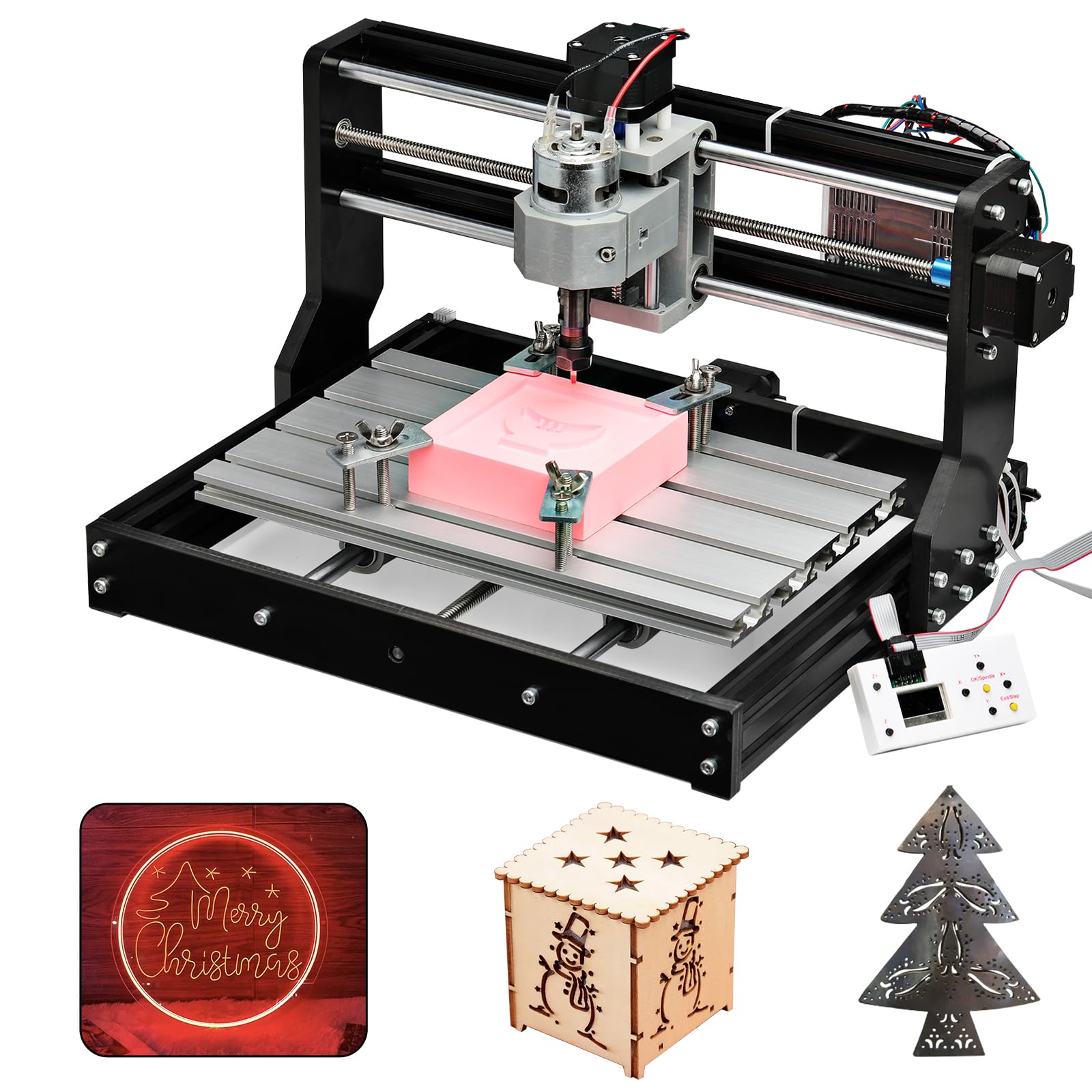

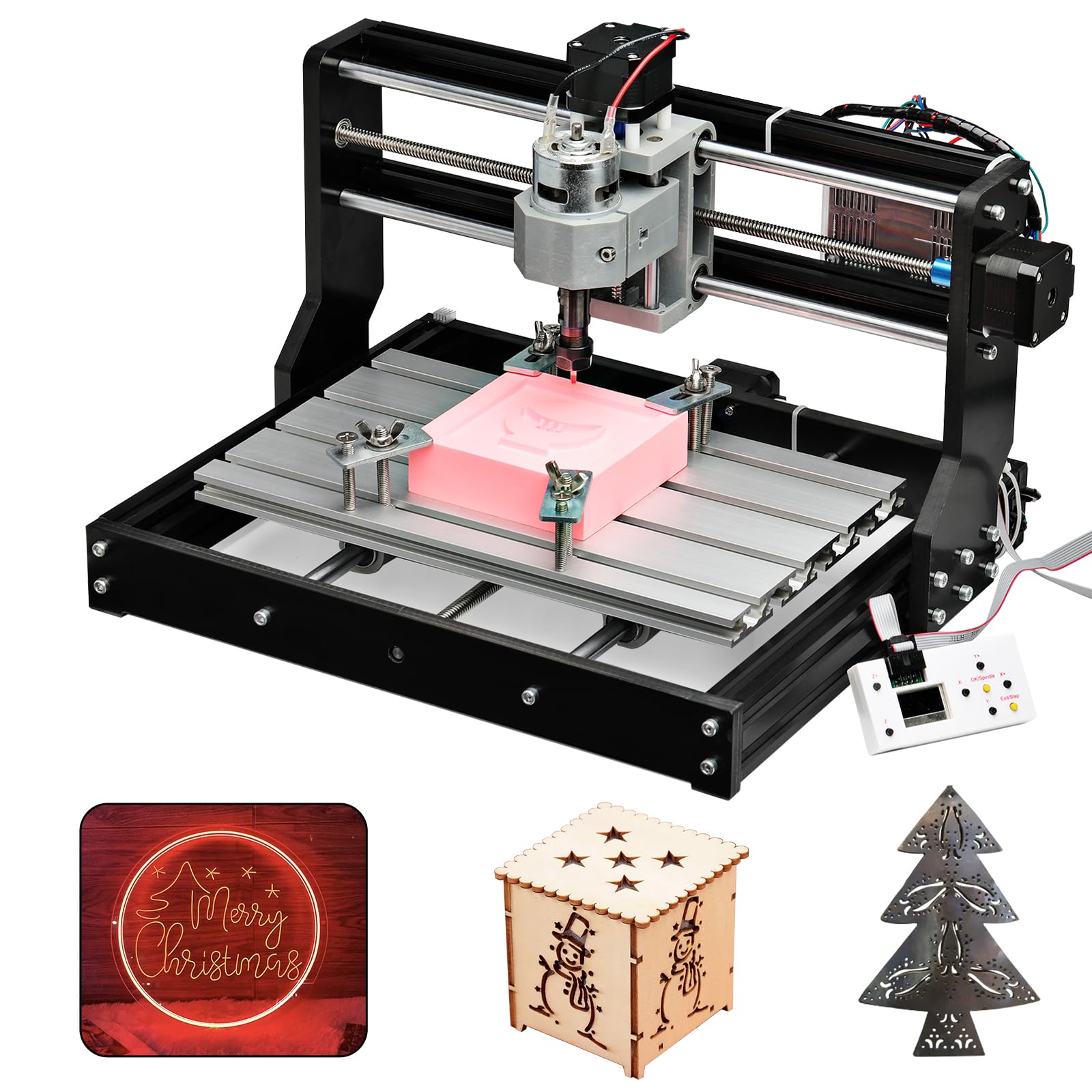

⚡ Unlock your maker potential with precision and power!

The Genmitsu CNC 3018-PRO is a professional-grade 3-axis router kit featuring a 300x180x45mm working area, upgraded easy assembly, and a powerful 20,000 RPM spindle. It supports a wide range of materials including plastics, soft aluminum, wood, acrylic, PVC, and PCBs. Controlled by industry-standard open-source GRBL firmware on Arduino, it offers extensive software compatibility and offline control. Perfect for hobbyists and professionals looking to elevate their CNC projects with reliable precision and expandability.

| ASIN | B07P6K9BL3 |

| Amperage | 1.3 Amps |

| Base Type | Fixed |

| Batteries Included? | No |

| Batteries Required? | No |

| Best Sellers Rank | #56,844 in Tools & Home Improvement ( See Top 100 in Tools & Home Improvement ) #2 in Power Milling Machines |

| Brand | Genmitsu |

| Customer Reviews | 4.0 4.0 out of 5 stars (1,902) |

| Date First Available | February 26, 2019 |

| Global Trade Identification Number | 00816550021620 |

| Horsepower | 120 |

| Included Components | Wood Carving Milling Engraving Machine |

| Item Package Quantity | 1 |

| Item Weight | 15.3 pounds |

| Item model number | 3018-PRO |

| Manufacturer | SainSmart |

| Maximum Rotational Speed | 1000 RPM |

| Part Number | B07P6K9BL3 |

| Power Source | Corded Electric |

| Product Dimensions | 7.09"W x 11.81"H |

| Style | 3018-PRO |

| Thickness | 0.1 Millimeters |

| UPC | 816550021620 |

| Voltage | 24 Volts |

C**D

Trust yourself and get this

I was just like you, reading reviews and contemplating if I should meander in to the world of CNC machines, a world that I know nothing about. If you're searching for these machines, you're already interested - so the only thing I can tell you is - get it. I have basic knowledge when it comes to electronics/hardware/software, if you're completely new to these things, the setup and usage may be slightly intimidating, but it IS easy enough that anyone can do it by following basic instructions. Like most mention - instruction manuals aren't the easiest to understand (for anything) but there are a ton of user videos all across the interwebs showing you how to set up/run the 3018. (seriously, if you need to learn anything, ever, about anything, ever, just YouTube or TikTok that ish) Out of box - I was a bit anxious. Any time you're opening a package that has hundreds of tiny parts it can seem like an uphill battle. If you dedicate a half hour or so of watching a set up video (all the way through), then setting it up while watching it again, it makes this set up a breeze. I had mine completed in about an hour, and after a minor issue was up and running. The V Bits that come with the machine are what I use most for cutting out designs. I also purchased some straight bits to use which, to me, are necessary if you're cutting out large pockets of material. As far as while this machine is running, people have mentioned noise quite often in reviews. I did not find the noise to be overwhelming. I have the 3018 set up in a room inside my house, and with the door shut, it doesn't disturb us at all. I use a Mac currently. I hate it, I was born and raised on a PC. So far I have found that Easel (it's a free application from inventables) is the easiest and most user friendly application to send G-Code, or your designs, to the machine. It's also incredibly user friendly for creating new designs for your 3018 if you're less than a novice and don't use any number of graphic suites (inkscape, illustrator, photoshop) along with Fusion 360 to create toolpaths for your designs. Windows users have a ton of more options to utilize your machine while connected to a computer, or you can upload your codes to the controller that comes with the machine to create your projects. I have used the 3018 quite often in the month I have had it. As always, there is trial and error involved. There is a learning curve when it comes to types materials to cut/carve at what speeds, and what types of bits to use. As you try a few projects here and there, you'll get much more comfortable about what to cut, and how to cut it. You can research and read about spindle speeds/materials/bits as much as you want, but you'll inevitably learn more from trial and error after having that basic knowledge from your prior research. So far I have mainly used MDF for my projects, though when attempting to use it on acrylic and copper, I can see the vast potential this machine has. CUSTOMER SERVICE for this product awesome. I had an minor issue during set up, and I was sent a replacement part incredibly quick. I was up and running the same week I received the machine. I have seen reviews complaining, but my experience reflects all of the glowing reviews about the help I received. This isn't a plug and play machine. You have to set it up. You have to learn it. At the price point, and with the capabilities this machine has - it is the PERFECT starter machine to get into the world of CNCs. All I can say is that you won't regret this if you try it. I'll upgrade the bed of the machine for larger projects, and eventually invest in the laser module to play with that as well. I would definitely recommend this machine and I would buy it again.

S**N

Insane value for the money.

The 3018 router is neither a production machine nor a toy. It is a solid hobbyist tool that is capable of producing excellent results. Assembly is straight forward with an excellent pictorial guide. Expect to put it together in an hour to a few hours depending on your experience. The unit is well designed and constructed. Tolerances are tight and there is no flex in the frame. The travel along the x and y axes measured precisely to spec out of the box. The kit comes with everything you need to get started including some bits and a disk with software. A word on software: Some reviews criticize the machine based on "software". The fact is that the firmware (the code that lives inside the controller board) is a recent version of GRBL, an open source program that is behind the vast majority of desktop routers. Every CAM program you are likely to use supports GRBL, so you will have access to a plethora of design tools to create your projects. Keep in mind that CNC is a 3 step process: 1) design the piece in CAD and export to DXF 2D format; 2) use CAM software to prepare G code by providing information on the bit, depth and order of cuts, and travel and rotation speed of the bit; 3) send the G code to the router with G code sender software. Don't be confused by the fact that some applications can combine 2 or even 3 of these steps. Like with 3D printing, it is very gratifying to start with an idea and develop it into a physical object. If you have the maker mentality this machine will provide great enjoyment and utility. UPDATE: My controller board stopped working--a very common occurrence for desktop routers due to the heat the motor drivers generate. I sent an email to Sainsmart describing the problem and within a few days they had a new board in the mail to me. After I received the board, their representative even followed up with me to make sure everything was working. This is the kind of customer service you love to have, and so rarely get. Even if you pay a few dollars more to buy from Sainsmart, it's well worth it. They will stand by their products.

D**S

This mini Cnc 3020 pro max arrived well packaged. This machine is well thought out because it is extremely easy to assemble because all the different parts are pre-assembled, the holes drilled and tapped. It is a comfort for any person (beginner, intermediate or confirmed). I followed the installation manual in English without difficulty. Everything is referenced and imaged. It took me nearly 45 minutes (unpacking + assembly) to get the final machine. This Cnc 3020 pro max has all the possible options. Nothing is to be purchased additionally. It has: a rigid aluminum plate of 30x20 cm, limit sensors, reinforced axis guides, a depth sensor, an external screen. There's even the micro SD card adapter included with the screen. The parts of the frame are massive and neat, it is a guarantee of quality. Safety is also an asset with its emergency stop and its box which hides the electronic part. All these options make this machine a reliable and efficient means of production. To improve the life of the top, it is advisable to install a martyr plate of the MDF wood type. Ideally, it allows rapid prototyping at home, in school to learn about engraving or machining easily. I carried out some tests using the Grbl software and the files present on the USB key supplied with the machine. Just connect the machine to the "Com port" with the USB cable. Grbl software icons are very intuitive. All you have to do is make the machine origin in x, y and z, then open the file and start machining. Whether engraving or machining, with tests on plastic or wood, the CNC is up to my expectations. I highly recommend her.

A**R

Shipment was quick and building the machine was easy. After a few runs the spindle motor stopped working. After contacting Tech Maker they shipped a new motor from China to the Netherlands in a few dates. Great product and great service!

J**R

Bra kvalitet, fungerar som den ska

M**K

I'd been down a YouTube rabbit hole watching CNC videos so I knew how these machines worked in theory. So long as you understand that this machine is small and designed for engraving you will be very satisfied. Working with hardwood has been a blast. Making small signs works great and I had been able to surface my material with a 1 inch surfacing bit without problems. Milling small items such as a ring box can take some time so making sure your g code is efficient will help. While working with hardwood (beech) I have found that a 1mm depth of cut produces a very clean finish without chatter. Personally I have been using 1/4 inch end mills with a cheap collet I purchased from amazon. The machine is very accurate and works great with very minimal setup. The most important feature of a CNC machine is rigidity. This is the reason I passed on all of the previous 3018 CNC's. This 3020 pro max is a much better design with much better components, and simply the best CNC engraving machine of its size available. This one is worth your money. I am very satisfied.

ヨ**オ

当初は安い事もあり、ノーマル3018の購入を考えていましたが自分の使用用途ではかなりカスタムする必要がありそうな為、思い切ってコチラを購入してみました。 結果的にこちらを購入して正解だったと思います。 筐体がほぼアルミ製という事でかなり剛性高く、コレなら吊るしで直ぐに使用出来そうです。(稼働は確認出来ましたが、置き場所の問題で切削まで出来てないです、、) 途中、ドライバーのインストールで不明点があったのですがサポートも良かったです。

ترست بايلوت

منذ شهر

منذ أسبوعين