معلومات عنا

حقوق الطبع والنشر © 2024 Desertcart Holdings Limited

💧 Cool your prints, heat up your creativity!

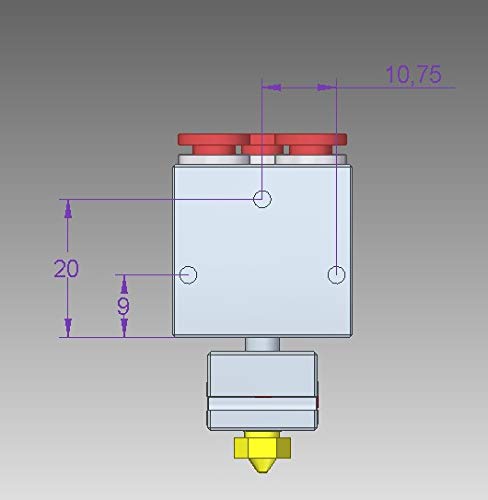

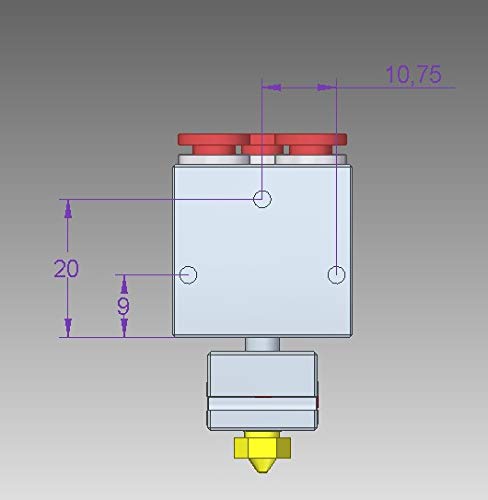

This all-metal, water-cooled 3D printer hotend features a 0.4mm nozzle optimized for 1.75mm filament, enabling high-temperature printing with superior thermal stability. Designed for Titan Aqua liquid cooling systems, it supports advanced temperature sensors and offers durable, precision-machined components for consistent, professional results.

| ASIN | B07LB2JBFY |

| Brand | NF |

| Brand Name | NF |

| Compatible Devices | Printer |

| Compatible Material | Plastic |

| Country of Origin | USA |

| Customer Reviews | 4.1 out of 5 stars 35 Reviews |

| Enclosure Material | Metal, Plastic |

| Manufacturer | POLISI |

| Material | Metal, Plastic |

| Operating System | Linux |

F**L

Built nicely, appears to work good.

Guess I'll be the first review this and I'll post my experience so far. First in all, I'm not sure what the proper system should be to get water flowing through this hot end. For now I bought fittings to use with a computer water cooling setup (pump, reservoir, and single-fan radiator.) I can tell you right now that there has to be a better way. This hot end uses the same type of hose that the filament uses for the water inlet and outlet. Because of that the small ID of 2.0MM restricts any short of high water flow. Especially since I'm using G1/4 water cooling fittings to 3/8" SAE hoses. I might try using the smallest section of the 4.0MM OD hose as possible and see if I can get better flow that way. So far I tried a print at 250C, and the temperature of the cooling block is at 28C which is my room temperature. So it seems to be working, just taking about 5 seconds to flow to the hotend and back to the single-fan radiator. As a note for others. As the description says; requires a 3.1mm temperature sensor, there is no threaded part like what I was hoping. I have a P100 sensor on it's way (need to go K-type soon) but since the heat break is the same size and thread as the E3D hotend I am using a E3D block for now. This hotend also comes with what looks like a brass nozzle. I am using a stainless steel nozzle instead. So let's talk a little about the heat break piece. It doesn't thread into the cooling block, instead it uses two set screws to lock it in place. I actually like this a bit better than the E3D screw on style. Because it won't seize in there. It's nicely machined as shown in the picture. I didn't try to use a E3D heat break, but it looks like it might be the same OD size. Only reason I'm thinking about that is if this part needs replaced in the future, probably won't be any alternatives. The heater cartridge uses the clamp style to keep it in place. Which I'm not a fan of, I'd rather have it use a set screw too. Mostly to prevent damage to the block, and instead to the heater cartridge.

E**.

much better than an air blown cooled heatsink, but...

it has a few design issues, one is that you can only put water through 4 mm outer diameter PTFE tubes, that means 2 or 3 mm inner diameter, limited water flow. It could do better with an inner diameter of 6mm, but that claims an outer diameter of 10 mm... However it works fine like that too, I am printing in an enclosure that can go as hot as 200C and cooling with a fan is not the option, this sytem brings me cold water from outside the enclosure where I have a small tank, a radiator and a pump to recirculate. Here is the trick, if the pump dies, your print goes bust, be sure you buy a persitaltic pump (not an aquarium rotary pump, they are not made to go on non stop for days) and make sure you have an air blower/fan cooling the pump body or it gets too hot to run.

J**.

Undicht !

Leider bekommt man die Schläche nicht dicht. Habe sie zum Testen eingeklebt, dann geht es gut. Leider ist der Aufwand gross das zu ändern, da nicht Eingeschraubt. Werde wohl 1/8 gewinde schneiden, und Nippel draufschrauben. Schade, sonst bleibt es kühl, mit G13 Kühlmittel.

M**O

Sembra tutto ok

Il prodotto sembra ok, non ancora testato ma sono ad soddisfatto della fattura. Consegna rapida

B**.

Beatifully machined hotend

I print PETG and PLA. For PETG I used a full metal hotend and for PLA i used the PTFE lined one so avoid clogging and heat creep. When I saw this hotend on Amazon I figured I could do both with one hotend a forever eliminate heat creep. The intended machine for this hotend was a Hyper Cube Evolution and since there was no carriage designed for this hotend I took the time to design and print one. At the same time I switched to a berd style cooling, etc. so it too a while before I was able to implement it. I spend a whole day rewiring the printer and the drag chain to get it so the tubes wouldn't be flopping around. Long story short I tried it, but then I switched back to a V6 hotend. Here is why: 1. I experienced clogging in the throat. Somehow the molten plastic ended up in the throat and setup there. Game over. Take it apart and clean it out and start over. 2. The red fittings are too tight for my PTFE tubing. Once you stick it in, it will not come out. Generally you should just have to depress the red ring and the tubing should release. I had to remove the throat and pull the entire tubing out the bottom. Here is what I like about it: 1. The machining is beautiful on all the parts. Best looking hotend out there 2. The heat bock is awesome. Clean, sharp edges, great threading... unlike the cheap heatblocks. I continue to use it on the V6 hotend. If I can find the block alone, I will buy some for my other printers. 3. It's very compact. I gave me another 5mm in the Z axis. Anyway, I wish I could have made it work, but the clogging was causing more frustrations than it was worth. I'll keep it just in case I want to take another run at it.

ترست بايلوت

منذ أسبوع

منذ 4 أيام