Customer Services

Copyright © 2025 Desertcart Holdings Limited

⚙️ Elevate your CNC game with precision power that professionals trust!

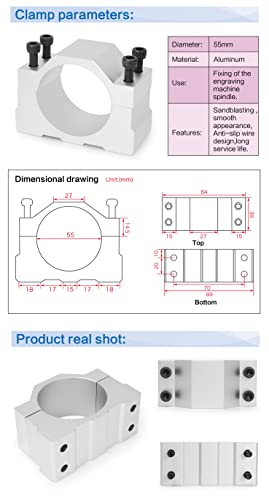

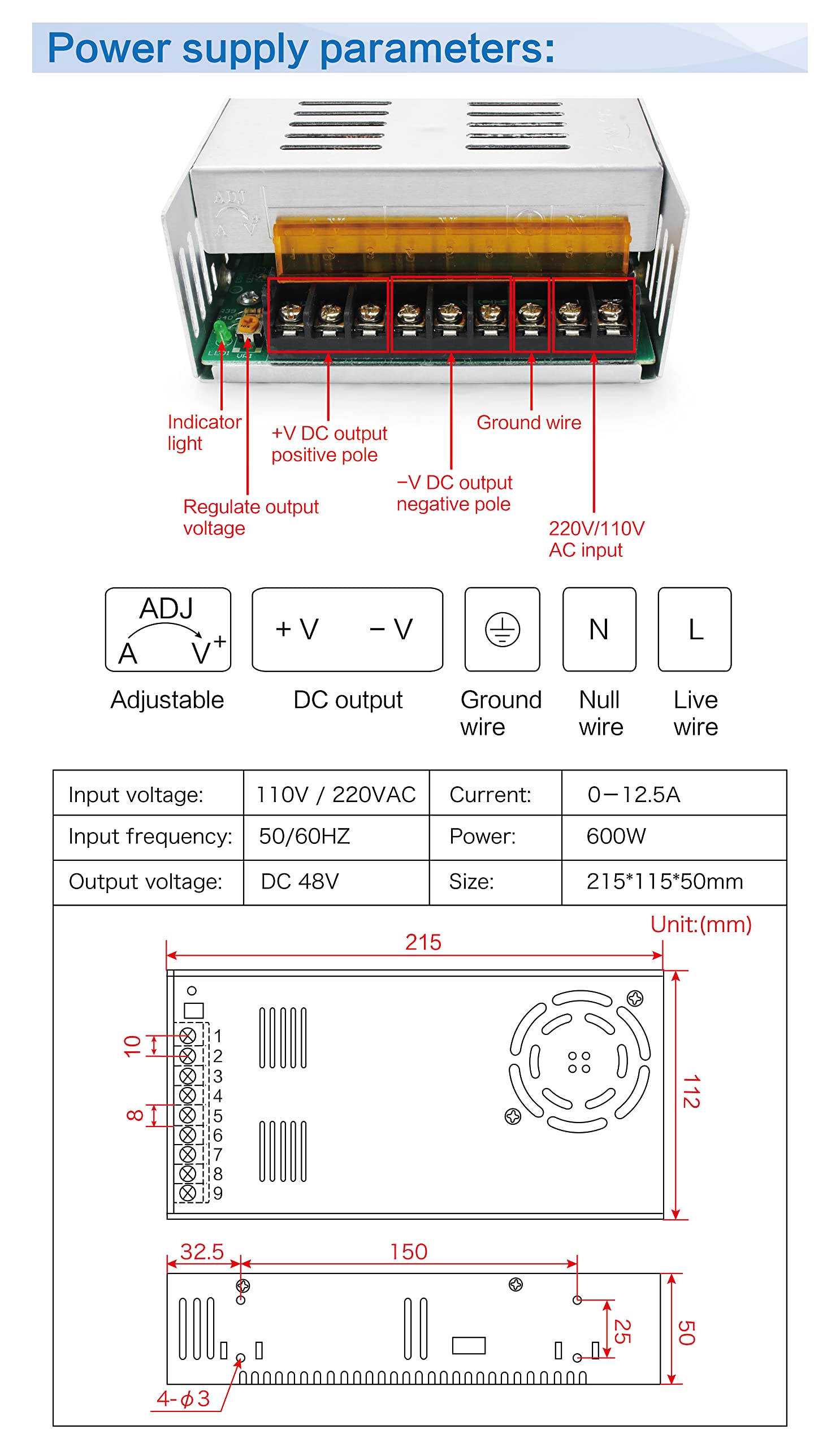

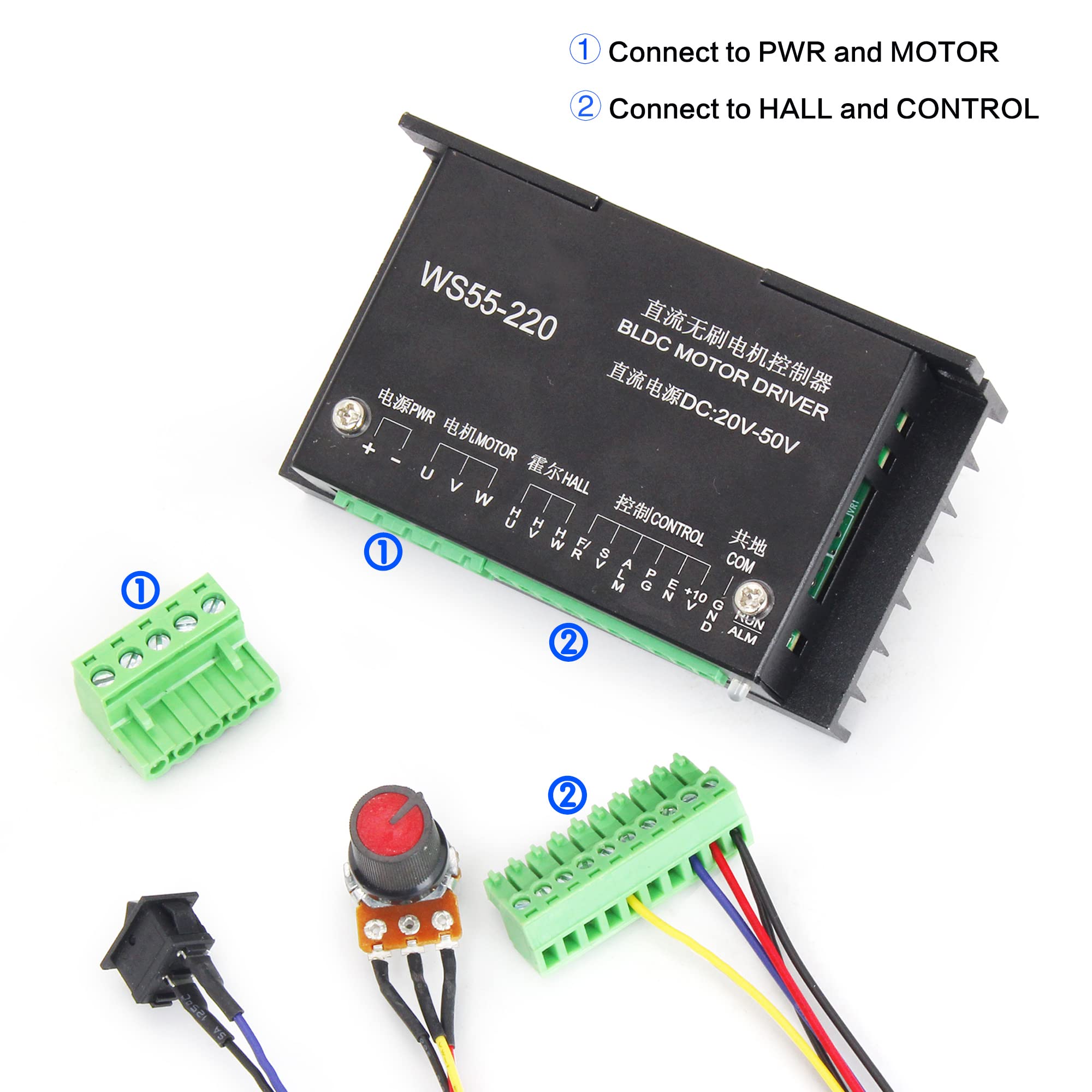

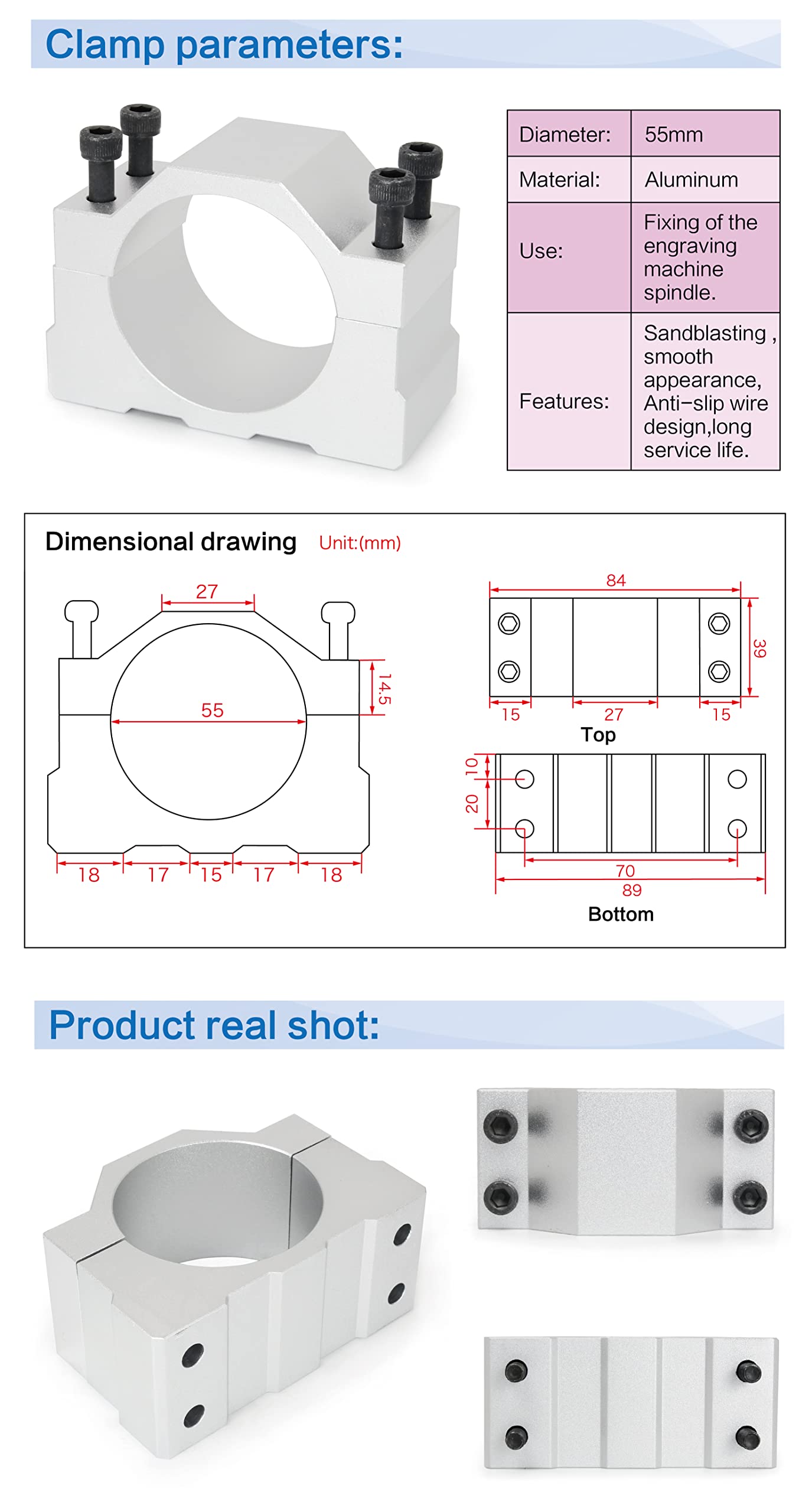

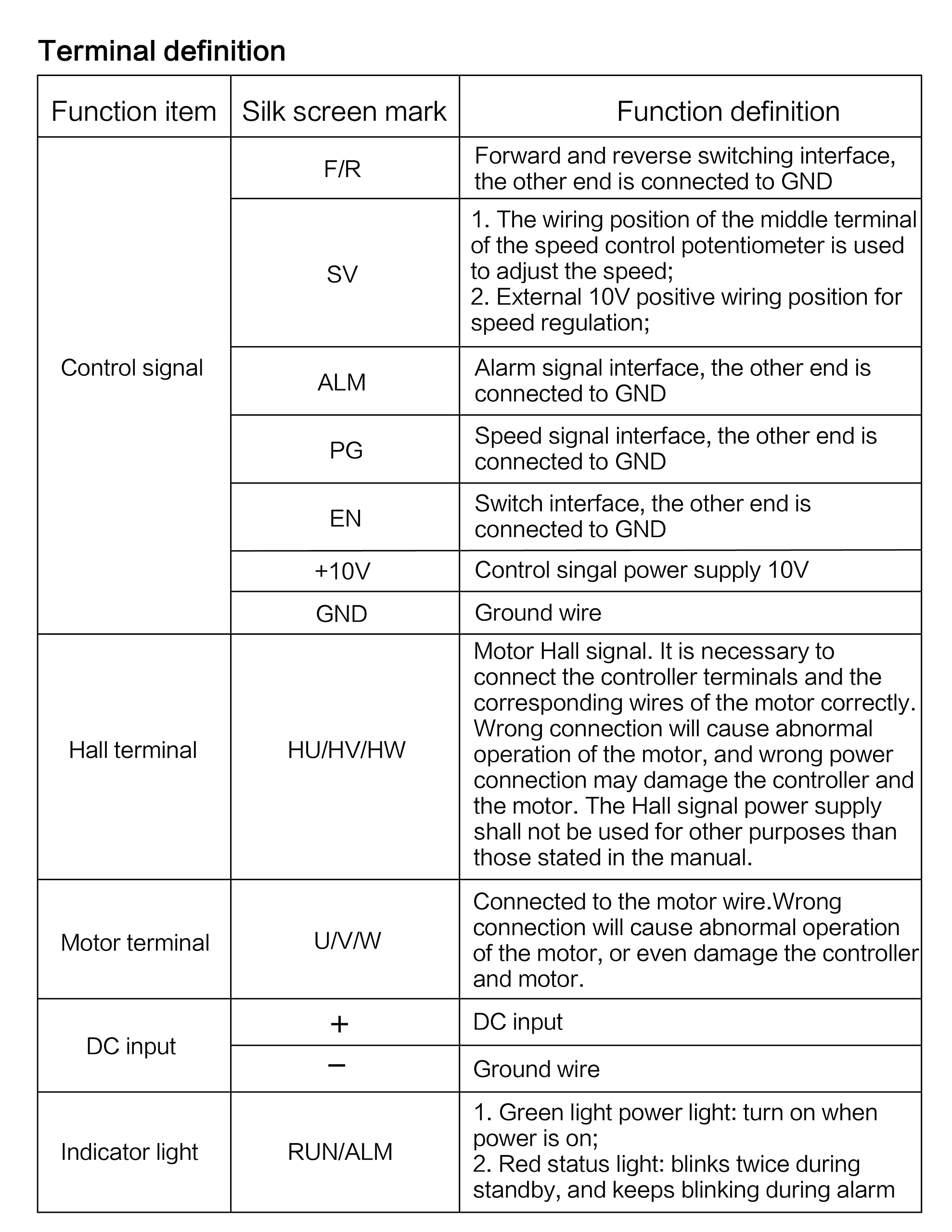

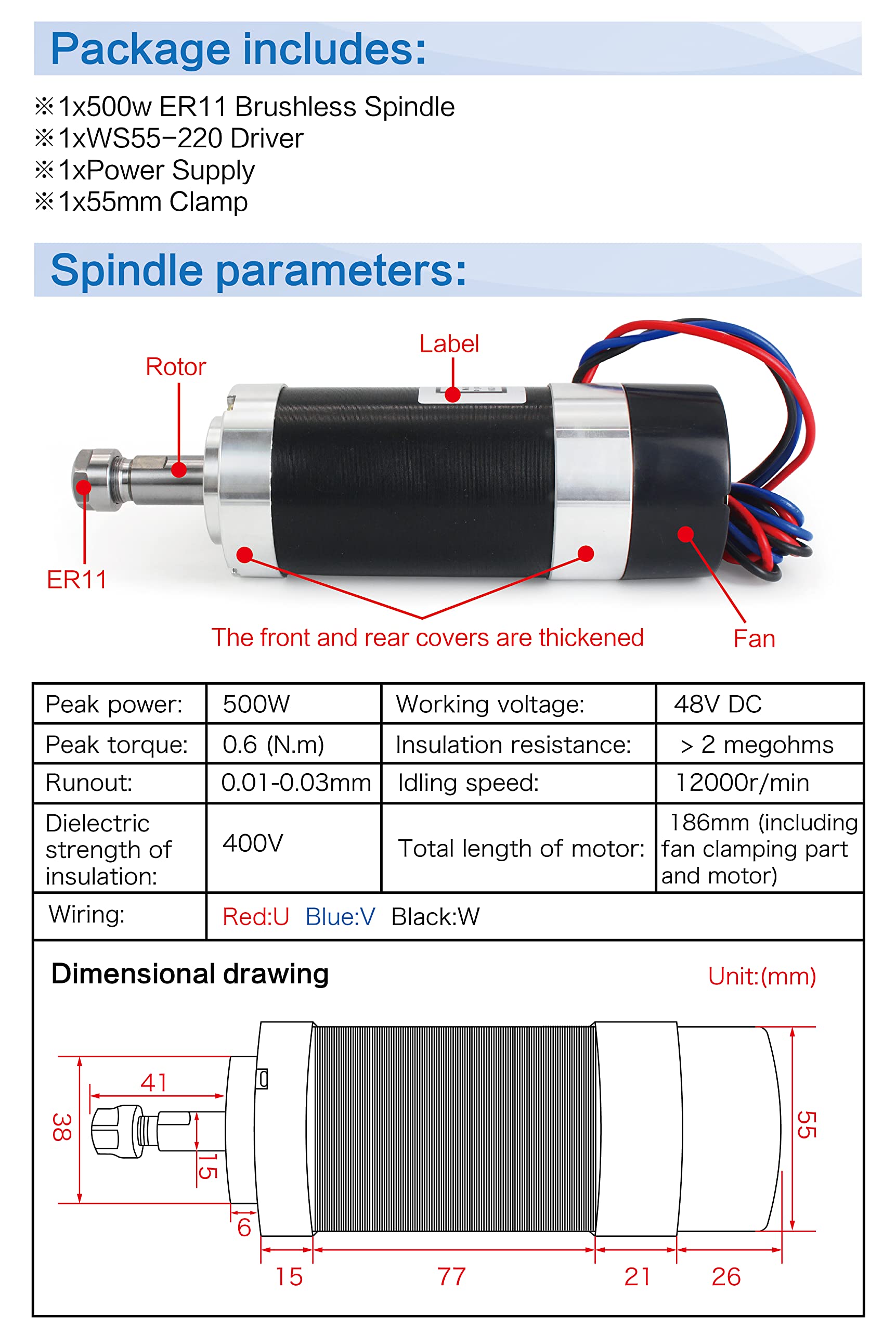

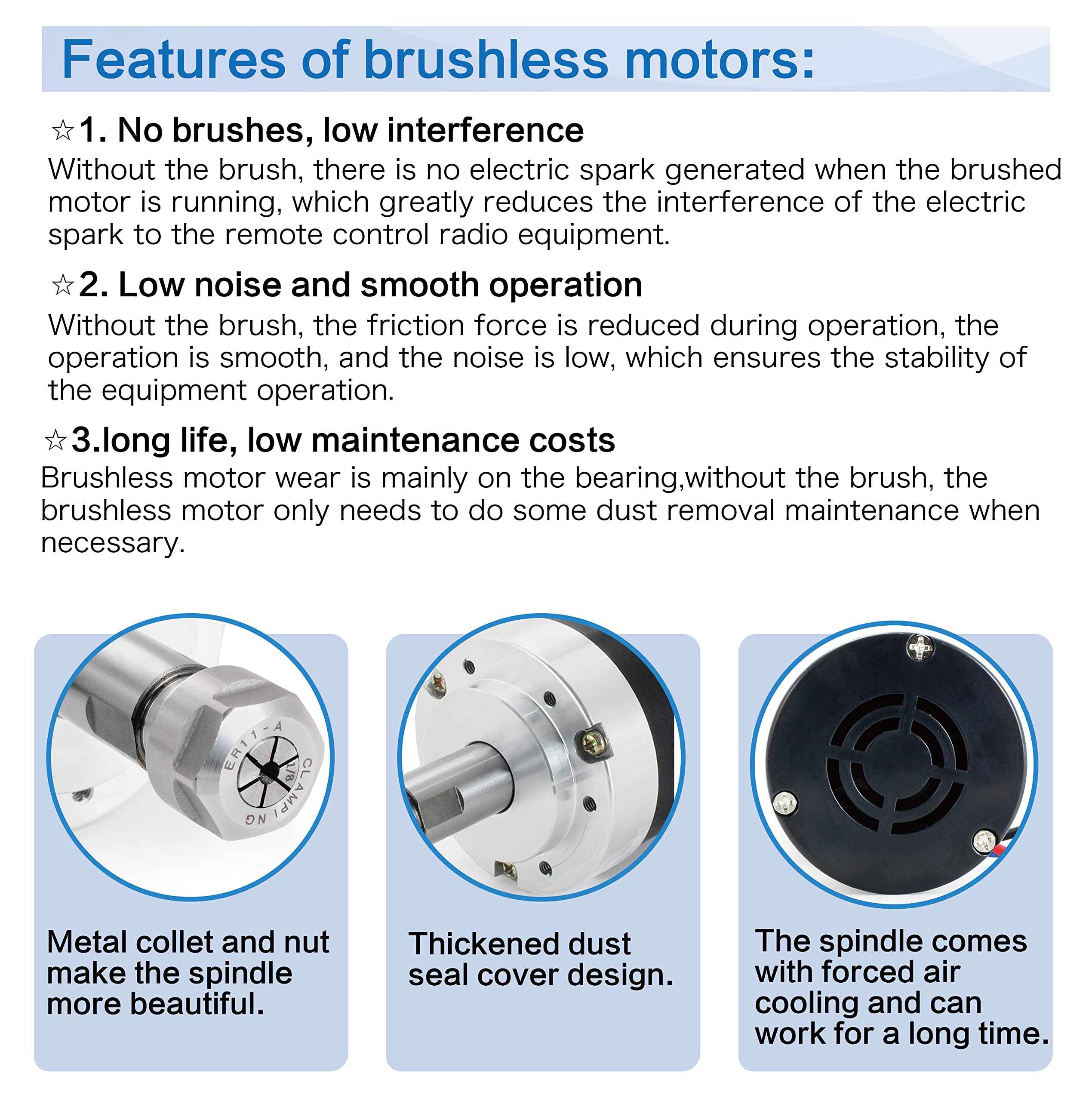

The RATTMMOTOR 500W CNC Brushless DC Spindle Motor Kit features a robust 48V air-cooled spindle motor capable of speeds up to 12,000 RPM and torque of 0.6NM. Its brushless design eliminates sparks and reduces noise, ensuring smooth, reliable operation. The kit includes a versatile brushless driver controller with multiple speed regulation options and a 600W DC switching power supply, making it a comprehensive solution for high-precision CNC routing with exceptional radial runout accuracy of 0.01-0.03mm.

| ASIN | B09X2Y63XQ |

| Best Sellers Rank | #175,034 in Tools & Home Improvement ( See Top 100 in Tools & Home Improvement ) #225 in Electrical Motor Controls |

| Item model number | 500WBLDC-4 |

| Manufacturer | RTM |

| Product Dimensions | 190 x 57 x 58 cm; 2.7 kg |

M**Y

I have been searching for so long for a spindle this accurate, measured runoff of 0.01mm so cutting with a 0.1mm tip gives you a 0.1mm cut, a 0.05mm tip becomes a 0.07mm cut which is still incredible. But it's stained and the finishing job is so strange I though it was used at first but it seems to be the manufacture focused more on getting it right than getting it pretty, if that's the trade-off for this level of accuracy then so be it. The power supply arrived dead-on-delivery, I have many others laying around the lab so I made it work, that the only real problem I encountered. Still gave it a 5-Star because this accuracy is almost impossible to find at this price

D**A

I received the new spindle assembly on 11-14-24. It looked basically ok, but the end cap on the motor looked slightly crooked to me, so I verified that it was angled by several degrees and then removed the end cap to inspect it. I found that the barrel outer casing of the motor had an edge that had been peened around the entire diameter. Possibly from beind dropped during manufacture. The end cap is intended to slip over this lip, so that a machined surface inside of the end cap would rest on the barrel of the motor. This it could not do. Instead, the end cap rested on this peened surface, and just ended up where it ended up. This end cap centers the motor shaft bearing, so the cocked end cap also cocked the bearing. I hand filed the protruding edge on the barrel so that the end cap could slip over it and seat properly. This allowed the bearing to seat properly. Once reassembled, I verified that the end cap mounting was true and found tbat the motor shaft now turned much more easily. I noted that the inside of the end cap had multiple raised casting burs that were sharp and were in close proximity to the tops of the motor coil windings. These burs were turned down on a lathe for safety. After reassembly, I connected the ESC and power supply, and they worked perfectly. Although not prewired, I tested the reverse function on the ESC, and it also worked perfectly. I am rating this product 4 out of 5 because the design is good and it met my needs, *but* the manufacturing flaws were hard to ignore. If you do not have the skills to deal with this sort of thing, then I recommend that you purchase a more expensive unit elsewhere that has been vetted.

R**R

Added this to my 1318 mill, works great and easily is integrated either MakerBase board via a $7 PWM to 0-10v board. Very low runout. And has the power to drive 1/4" bits through wood or 1/8" through light metals easily.

M**T

Why do you even make BRUSHED motors anymore There is no comparison in quality, ………. It’s a waste of time and money to continue to make BRUSHED motors!!!!!!!!!

A**R

Seems good so far and runs at low speeds pretty well, quiet and strong. One warning, the power supply has a 110v/220v switch on the side, mine was set at 220v, the motor still ran but was lower rpm, after switching to 110v, I seem to get full speed

Trustpilot

1 month ago

1 week ago