Customer Services

Copyright © 2025 Desertcart Holdings Limited

⚙️ Cut with confidence, finish like a pro!

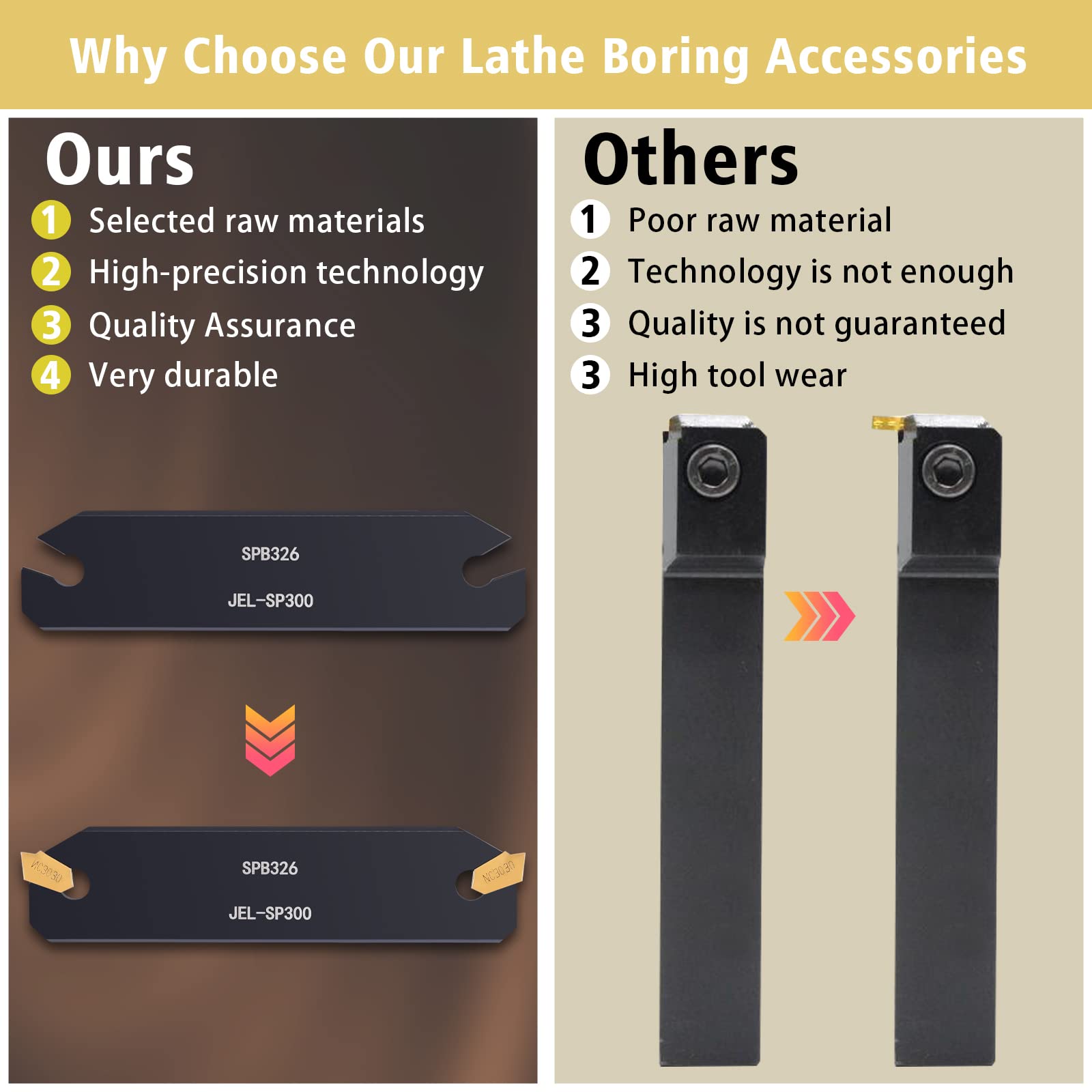

The VerRich Lathe Parting Tool SPB326 combines a robust tungsten steel holder with 10 precision GTN-3 NC3030 carbide inserts featuring PVD coating, delivering superior hardness and speed. Designed for deep, fine grooving and semi-finishing on stainless steel and tough alloys, this 110mm tool offers durability, impact resistance, and organized storage—making it a must-have for professionals seeking reliable, high-performance lathe cutting.

| ASIN | B083KJJMRF |

| Best Sellers Rank | 5,215 in Business, Industry & Science ( See Top 100 in Business, Industry & Science ) 3 in Power Lathe Turning Tools |

| Brand | VerRich |

| Colour | Black-type 3 |

| Country of Origin | China |

| Customer Reviews | 4.5 out of 5 stars 594 Reviews |

| Included Components | SPB26-3 Cut-Off Blade, Cut-Off Grooving Inserts (10 pieces) |

| Included components | SPB26-3 Cut-Off Blade, Cut-Off Grooving Inserts (10 pieces) |

| Item Dimensions L x W x H | 3W x 26H millimetres |

| Item Weight | 0.09 Kilograms |

| Item weight | 0.09 Kilograms |

| Manufacturer | VerRich |

| Material | Stainless Steel |

| Model Name | SPB26-3 |

| Model Number | SPB326+NC3030 |

| Power source | hand_powered |

| Recommended Uses For Product | Steel Semi-Finishing |

| Recommended uses for product | Steel Semi-Finishing |

| Special Features | Suitable for Steel Semi-Finishing |

| Special feature | Suitable for Steel Semi-Finishing |

| Style | SPB26-3 |

B**E

good price

just the job im a beginner and thease seem well made

B**.

Good value, well made, good price.

Boring 316 s.stl.

C**S

Seem good for the money

After using the tools on a job the other day they certainly don’t seem bad for the money.

M**K

Better for softer material

Might be ok for cutting softer materials like brass no good on steel

J**R

Tools

Well made tools

J**N

Thanks

Thanks

K**D

Tips are useless

As described size wise although the tips are absolutely useless, Won't cut ti, steel, copper

I**D

Flimsy

Used twice (once each end!) for parting mild steel as a stop-gap whilst waiting for new Iscar blade. Both times the insert pockets of the blade stretched and tool stopped cutting due to insert being pushed too deep. Blade is not hardened sufficiently to withstand cutting pressure under slow power feed parting.

Trustpilot

2 weeks ago

2 days ago