Customer Services

Copyright © 2025 Desertcart Holdings Limited

📐 Measure Like a Pro, Lead Like a Boss!

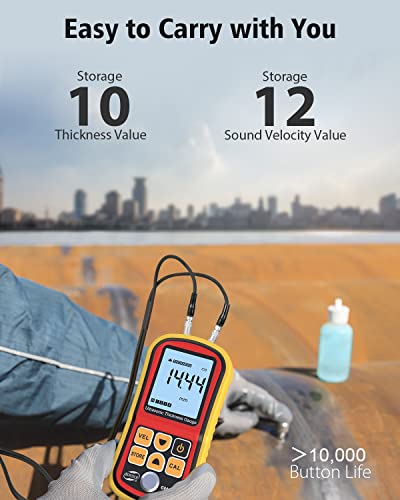

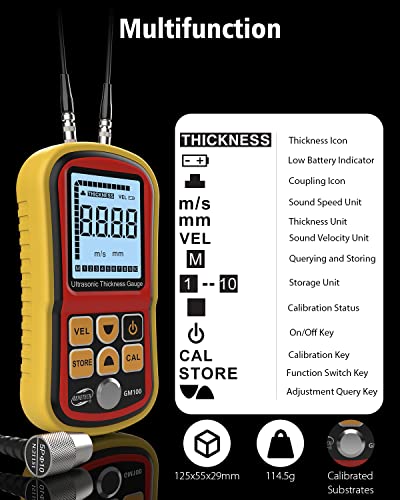

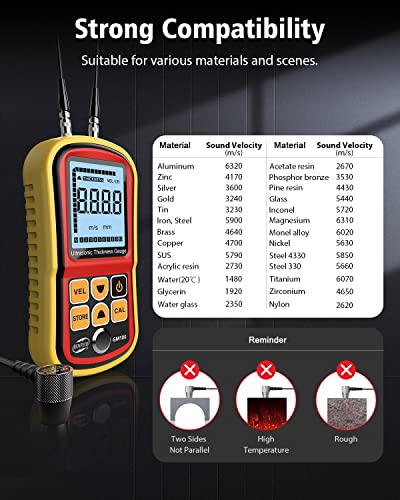

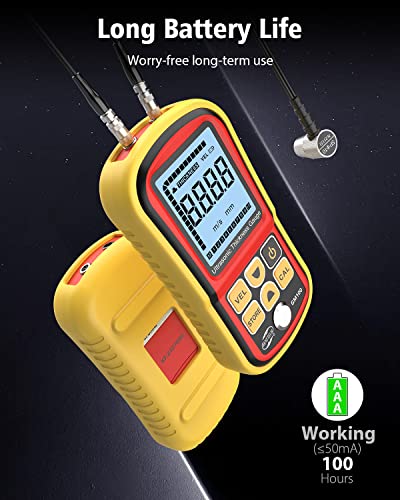

The BENETECH GM100 Digital Ultrasonic Thickness Gauge delivers ultra-precise thickness measurements from 0.039 to 8.85 inches with lightning-fast 0.5-second readings. Featuring adjustable sound velocity calibration, a vivid HD color LCD, and robust data storage, it’s engineered for professionals measuring metals and non-metals alike. Complete with a probe, calibration blocks, and protective cover, this tool combines accuracy, speed, and convenience—backed by 24/7 expert support and a 12-month warranty.

| ASIN | B0C32WYY58 |

| Best Sellers Rank | #12,440 in Tools & Home Improvement ( See Top 100 in Tools & Home Improvement ) #15 in Thickness Gauges |

| Item model number | GM100 |

| Manufacturer | BENETECH |

| Package Dimensions | 28.8 x 19.41 x 8.1 cm; 453.59 g |

E**Z

Ok

Na

T**E

Everything I expected

A**Y

I work in a paper mill as a reliability engineer and I wanted to test it against certified technicians we hire for thickness measurements of many many things ($$$$). The goal was tu measure pipe thickness and prevent leak overtime by erosion. The test was done on 316 stainless, 14" pipe 10 gsuge at 75c. It was not specifically calibrated for stainless steel but still the results were within 3% of the "pro" equipments. We made a calibration sample in different material and so far, the result are amazing. The case is also helpful at maintaining it in clean an industrial environment. Really having fun with it!

R**H

The ultrasonic thickness gauge comes in a nice travel case with the requisite batteries, coupling gel, probe, 4.0mm steel test disc and a manual. Usage is fairly easy once you figure it out, but you'll need to interpret the instructions to figure out what they're trying to say. The gauge is continuously scanning for thickness, but you must apply the coupling gel for it to show you a reading, this was a bit confusing at first but makes sense. There is no "begin scan" button, it just detects when you have the probe on an item with the gel applied and displays the thickness. After calibrating the gauge to the center metal button (with gel of course,) I took some measurements and compared them to readings from my digital micrometer which is accurate to 0.0001", quite a bit overkill for this test as this gauge has a precision of only 0.1mm but it's what I had. The gauge reported the 3.996mm thick metal disc as 4.0mm (at the recommended sound velocity of 5690m/s. After adjusting the gauge to the recommended glass velocity of 5440m/s, a 1.340mm thick glass pane was reported as 1.1mm thick. Granted the glass was on the thin side, but not outside the minimum stated limit of 1.2mm. The accuracies in the manual are specified as follows: At less than 20mm thickness: +/- 5% Above 20mm thickness: +/- 1% +0.1 Total measuring range is only stated for steel at between 1.2mm and 225.0mm. The sound velocity can be set to anything between 1000m/s and 9999m/s which is quite the range. You can store a programmed velocity into one of the memory slots. You can also save a measured value into another memory slot. One of the most interesting features with this gauge is its reverse measurement ability. If you have a material sample of unknown type, you can measure its thickness with your micrometer, program the thickness into the unit, and it has the ability to report the sound velocity it used to obtain that thickness. Once you have the correct velocity you can proceed to measure the thickness of other items made of the same material. This is quite useful when you have no idea what the material is but can follow this process and measure its thickness anyway. Overall a very interesting tool. If you need an affordable ultrasonic measurement gauge this is a decent choice. You will however need a source of ultrasonic coupling gel, especially if measuring the through-thickness of a lengthy weld as the gel must be present at all points of testing.

G**Y

I like this one a lot more the blue one.ihave had for about two years and still like it

K**H

I bought this to determine types of metals, such as silver or silver plate on steel, etc. This is done by measuring the sound velocity through the metal. The printed instructions tell you how to do this. The device does not work like the instructions tell you it should. The up and down arrow keys will not work as described. You cannot read-out the sound velocity so you cannot discern the type of metal. Also: Only reads out in mm, inches are not available. Key feature Sound Velocity Detection is not available to the user. When compared to a micrometer the thickness measurement of steel seamed to be very accurate.

Trustpilot

1 month ago

2 weeks ago