Some deliveries may take a little longer than usual due to regional shipping conditions.

Customer Services

Copyright © 2025 Desertcart Holdings Limited

⚙️ Own the precision edge every pro craves!

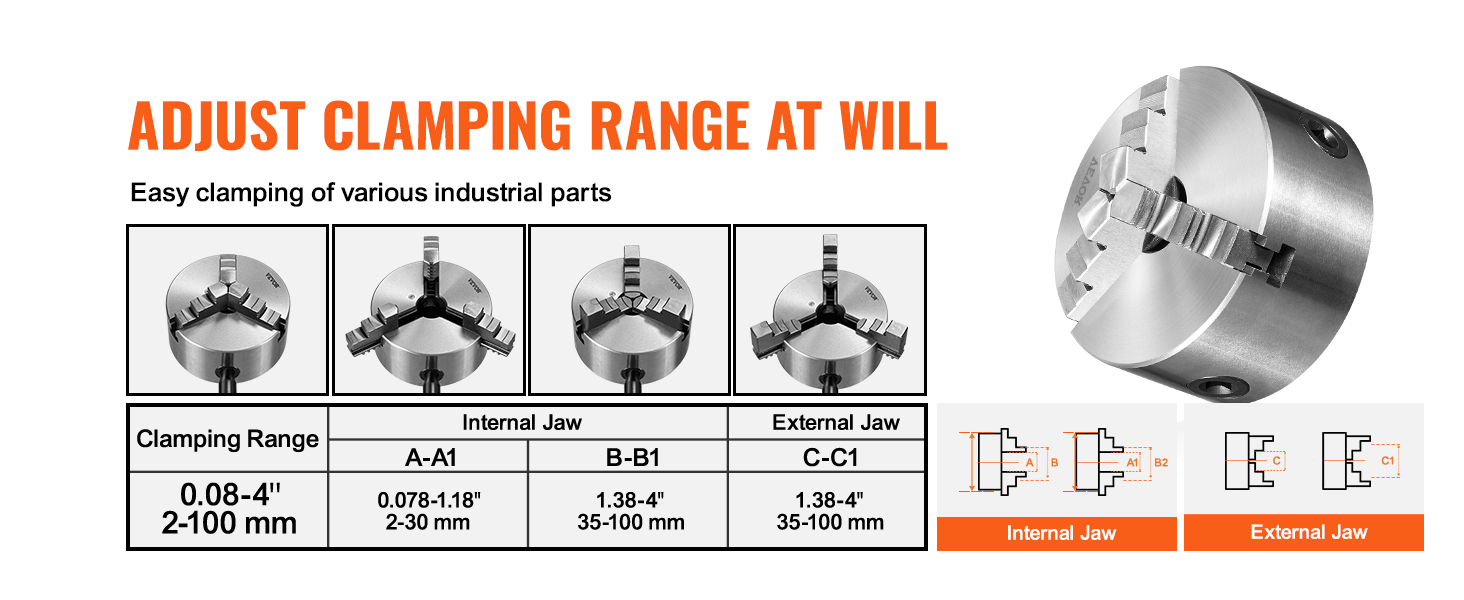

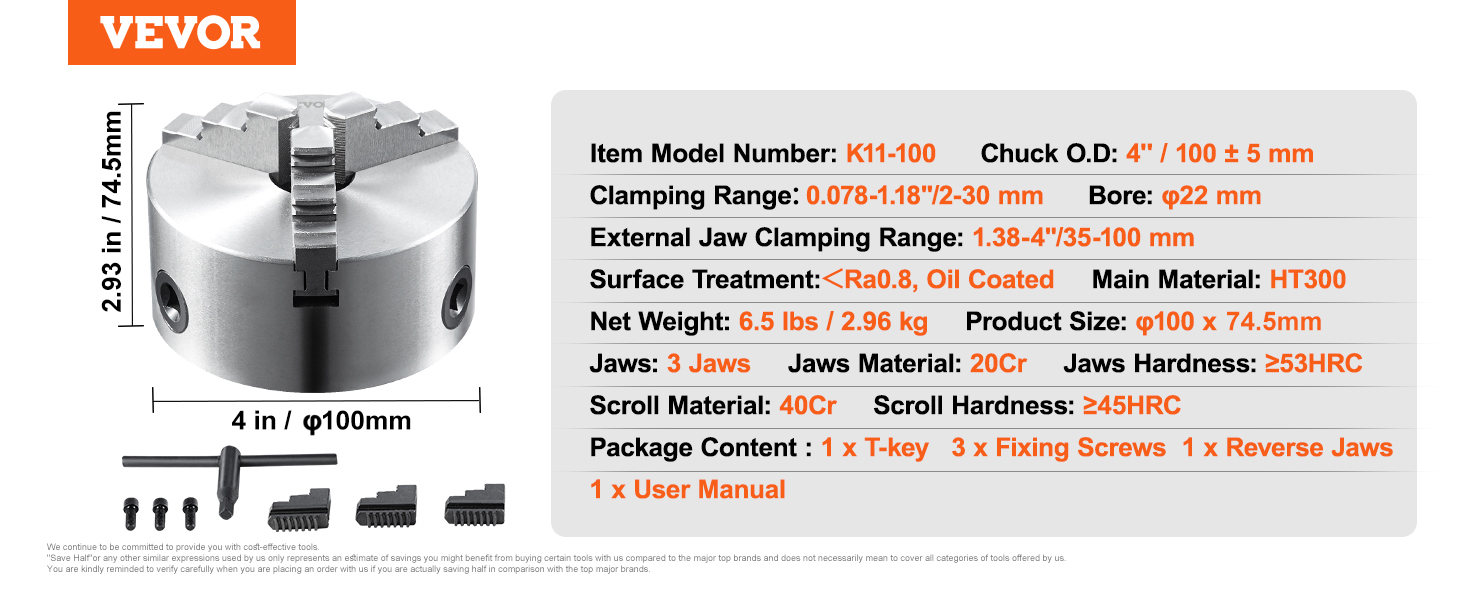

The VEVOR 3-Jaw Lathe Chuck is a premium self-centering chuck made from hardened HT300 alloy steel, featuring a wide 0.08-4 inch clamping range with reversible jaws. Designed for high-precision machining with ≤0.05 mm tolerance, it offers effortless operation via T-key fixing screws and fits a variety of machines including lathes, milling, drilling, and 3D printers—perfect for professionals demanding reliability and versatility.

| ASIN | B0CG9J3N7Q |

| Best Sellers Rank | 101,756 in Business, Industry & Science ( See Top 100 in Business, Industry & Science ) 107 in Power Lathe Chucks |

| Brand | VEVOR |

| Capacity | 2.96 Kilograms |

| Compatible Devices | Drilling Machine, Lathe, Milling Machine |

| Compatible devices | Drilling Machine, Lathe, Milling Machine |

| Customer Reviews | 4.2 out of 5 stars 107 Reviews |

| Handle Type | T-key |

| Included Components | 1 x Reverse Jaws, 1 x T-key, 1 x User Manual, 3 x Fixing Screws |

| Item Diameter | 4 Inches |

| Item Type Name | 4'', Self-Centering Lathe Chuck, 0.08-4 in/2 -100 mm Clamping Range with T-key Fixing Screws Reversible Jaws, for Lathe 3D Printer Machining Center Milling Drilling Machine |

| Item Weight | 6.83 Pounds |

| Item diameter | 4 Inches |

| Item height | 4.72 inches |

| Item weight | 6.83 Pounds |

| Lock Type | Self Centering |

| Manufacturer | VEVOR |

| Material | Alloy Steel |

| Thread Size | M8 |

| Thread size | M8 |

| UPC | 840349952260 |

R**L

Fantastic quality and workmanship

Outstanding piece of quality and precision machinery. These people know what quality means! This lathe chuck is worth every penny, i am verry happy with it! Thank you

R**3

seemed very good but didn't fit my lathe

to small for my lathe

K**R

Brilliant quality

Brilliant quality and a bargain at the price

J**S

K11 200

To be honest its a generic asian made chuck with various brand names and no names, i expected the worst having bought thm in the past and ended up junking. Upon opening i tried the jaws, as ever felt notchy and quite stiff to move. Decided it was bearable and time is money, more so considering the cost at £91 and set about getting it on the lathe. Turned the register within 1 thou, drilled the holes through etc, mounted the chuck to find the jaws were 13 thou runout. Means cannot do what i need to do daily after using a £1373 Bison chuck last 14 years. Two options, send back and lose days of downtime or make it right which is what i ended up doing in piccies. Had to enlarge the 10mm fixing holes to 11mm each and larger 16mm counterbore. Then turn register down at least 0.796mm undersize (seen at piccy 6) to allow chuck offset and centring of the jaws within 0.5 of a thou. Obviously if your a diyer you wont know any difference or if make things in one without the need to turn the part round you would be ok. If not as most engineers are, you will need to fix its problems i half expected when purchased. Chuck key is also larger square fitting than Bison, yes that is a plastic backing cover inside the 165mm register.

Trustpilot

2 months ago

1 week ago