Customer Services

Copyright © 2025 Desertcart Holdings Limited

⚙️ Elevate your robotics game with precision that speaks volumes!

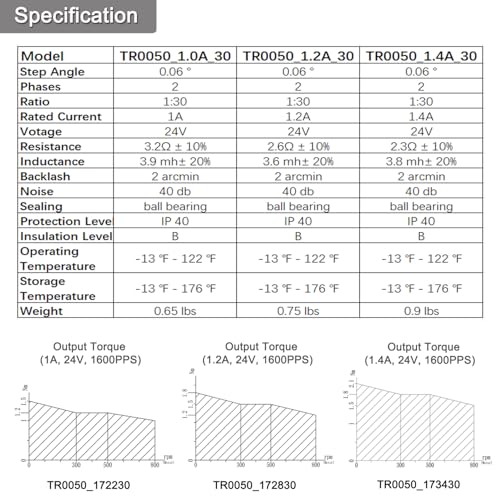

The PGFUN Harmonic Gear Drive Reducer with NEMA 17 Stepper Motor combines a high-precision 30:1 gear ratio and minimal 2 arcmin backlash to deliver smooth, accurate rotary motion. Rated at 1.4A and 24V with a recommended torque of 2.1 Nm, this compact 0.4 kg unit is perfect for DIY robotics and lightweight rotary platforms. Its quiet operation and IP40 protection make it a reliable, cost-effective choice for professionals seeking precision without compromise.

| ASIN | B0BQ3S5V6J |

| Batteries Included | No |

| Batteries Required? | No |

| Customer Reviews | 4.0 4.0 out of 5 stars (2) |

| Date First Available | February 24, 2023 |

| Horsepower | 2.1 Watts |

| Included Components | Harmonic Drive Recorder with Step Motor, 4-Wire Cable |

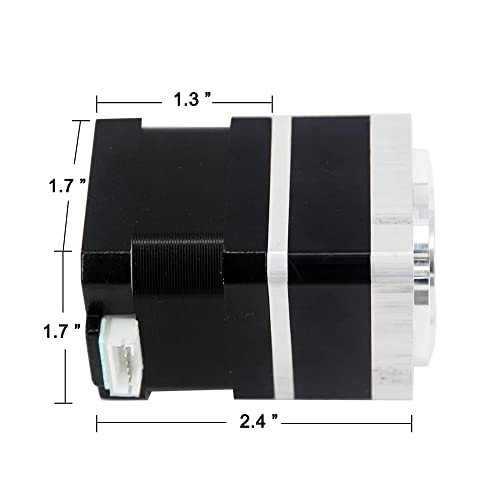

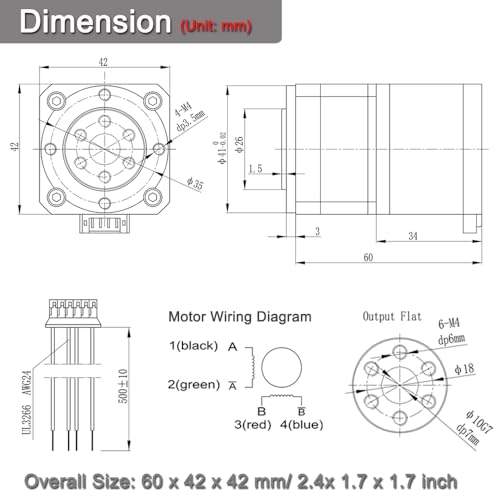

| Item Dimensions LxWxH | 42 x 42 x 60 mm |

| Item Weight | 440 g |

| Manufacturer | PGFUN |

| Material | Metal |

| Part number | TR0050_173430 |

| Product Dimensions | 4.2 x 4.2 x 6 cm; 440 g |

| Size | 1.4 A |

| Style | Nema 17 |

| Voltage | 24 Volts |

C**D

Harmonic drives are normally very expensive. I have had my eyes on these for a little while and finally had a project that could use a three of them. There is a lot to like, they are compact, nearly silent with a low noise driver, and easy to drive. I really like the top plate, and wish more motors had a similar design. They claim 2 arc min backlash and they have no percieveable backlash. Also at $125, they are a fraction of the cost of a typical harmonic drive. I could imagine these being very useful in many applications. In my case i was working on a motion control robot for a client, and the issue comes in when you start to drive them with any load, the movement starts to sort pulse. The load was 100% suppported by a large RU66 style german bearing, and all these motors had to do was apply a rotational force to the rotational side of the bearing. All metal contact through out, and as soon as things started moving it would start to pulse. I added a mechanical damper to add a little extra resistence to the motor which did help, but unfortunatly the issue was still noticable. I swapped them out for a couple worm drives and the issue cleared. They worked better at extremely slow speeds < 2-3 degrees per second. I imagine these would be super handy for many purposes, but if you need consistent smooth confidant motion. Keep your load requirements very light.

Trustpilot

1 week ago

3 days ago